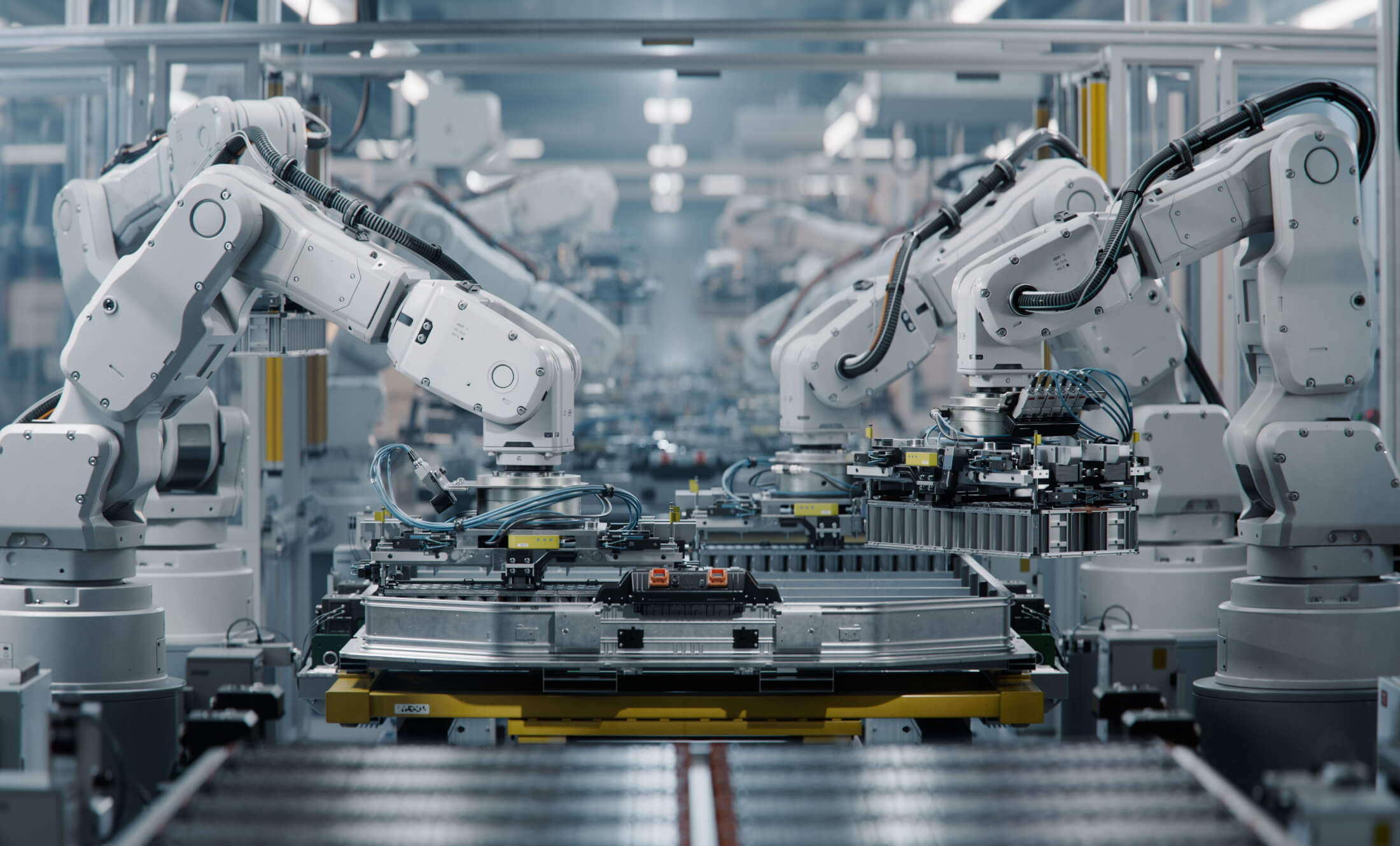

Maintenance, Repair, & Fabrication

Equipment Maintenance for Peak Performance

Need Industrial Equipment Repair?

Poor maintenance or outdated components can lead to costly repairs, unplanned downtime, and lost productivity. Our maintenance, repair, and fabrication services ensure your equipment stays in top condition and performs at its best. Whether it’s fixing a malfunction, replacing worn-out parts, or fabricating custom components, we’re here to extend the lifespan of your machinery and keep your operations running smoothly.

Automation Repair Services

We specialize in providing comprehensive automation maintenance, and fabrication services designed to ensure your systems run smoothly and efficiently. Our focus is on delivering solutions that minimize downtime and keep your operations on track.

- Control Panel Fabrication

- Shop Diagnostics and Troubleshooting

- Shop Electrical & Mechanical Component Repair or Replacement

- Factory Acceptance Testing (FAT)

- Field Startup & Commissioning

- On-site Deployment, Testing, and Integration of Automation Systems

- On-site Diagnostics and Troubleshooting

- On-site Programming Diagnostics or Modifications

- On-site Electrical & Mechanical Component Repair or Replacement

Ongoing maintenance is crucial for the life any system. Here’s how we ensure flawless performance for your automation equipment.

Expert Diagnostics

We use advanced tools and predictive maintenance to quickly find and fix electrical and mechanical problems in automation equipment.

Custom Fabrication & Component Repair

Our team specializes in fabricating custom control panels and components to meet your specific needs, ensuring your automation systems run smoothly year round.

Seamless Integration & On-Site Support

We offer on-site deployment, testing, integration, and training of automation systems, ensuring smooth installation and integration into your manufacturing process.

Quality Assurance

We use Factory Acceptance Testing (FAT) to ensure automation systems meet the highest quality standards before they are deployed in the field or in the assembly line.

Equipment Repair Technicians in Texas

We assist industrial facilities, refineries, and manufacturing plants in Houston, the Gulf Coast, and across Texas. Our team provides regular maintenance, quick repairs, and custom fabrication to ensure their equipment runs smoothly and efficiently. We understand the demands of these industries, and offer tailored services to prevent costly downtime. Whether it’s emergency repairs or routine upkeep, our goal is to keep your processes at peak performance.

Why Kraken Engineering?

Tailored Maintenance

We provide custom regular maintenance services to meet the specific needs of your automation equipment, ensuring maximum operational efficiency and uptime.

Rapid Response & Support

Our team offers quick service with on-site support, personnel training, and remote monitoring to optimize continuous performance, all while reducing repair costs.

Long-Term Maintenance

We offer long-term maintenance solutions to ensure your machine learning and automated systems run smoothly, helping to extend the lifespan of your equipment.

Repairs & Upgrades

We offer retrofitting and replacing parts to enhance performance without forcing you into costly full-system replacements,.

Hands-On Service & training

We understand your needs and provide hands-on maintenance support and training to boost efficiency and product quality.

Multidisciplinary Expertise

We bring over 25 years of experience in automation and control systems to every maintenance, repair, and automation project.

#THISISKRAKENAI

Powering Innovation

ThisIsKrakenAI is Kraken Engineering’s media hub on all platforms. Together with OGGN, our experts share industry news through trade show podcasts, dynamic social content, and insightful blog articles.

What is Manufacturing Automation? How We Can Help

With the rise of technology and AI, manufacturing solutions are starting to resemble the stuff of...

New Website Launch for Kraken Engineering!

Kraken Engineering is proud to announce the launch of our new website! Our new website is an...

Join the Kraken Engineering Community!

We want to invite you to join our extended community. This is your opportunity to connect with us...

Uncharted Questions

How often should I schedule maintenance?

The best servicing schedule depends on your equipment and how often you use it. In general, we recommend routine inspections and maintenance every 6 to 12 months. Our maintenance, repair, and fabrication services help keep your systems running smoothly, catch potential problems early, and prevent costly breakdowns.

Do you offer 24/7 emergency repair services?

Yes, we offer 24/7 emergency repair services, ensuring that no matter when an issue arises, our team is available to address it promptly and minimize any unplanned downtime to keep your operations running efficiently. If you have an urgent need, contact our team for assistance.

Can you fabricate custom replacement parts?

Absolutely! Our custom fabrication services allow us to design and create precise, high-quality replacement parts tailored to your equipment’s specifications, ensuring optimal performance and a perfect fit.

Do you regularly maintain aging industrial control systems?

Yes! We provide maintenance, repair, and fabrication services for older industrial control systems. Our team creates custom maintenance plans to keep your equipment running smoothly, helping prevent breakdowns and expensive repairs. We also offer control systems integration and retrofits to replace old parts with modern automation technology, making your system more reliable and efficient.

How do I know if my equipment needs repairs?

We offer diagnostic services to assess the performance of your equipment. Warning signs such as unusual noise, vibrations, or decreased efficiency often indicate a need for repairs. Our team can identify and address these issues early to prevent further damage. If you have an urgent need, contact our team.

Transform Your Operations

Ready to explore how automation can improve your processes? We offer a free consultation to review your organization's capabilities and areas where automation would prove beneficial.