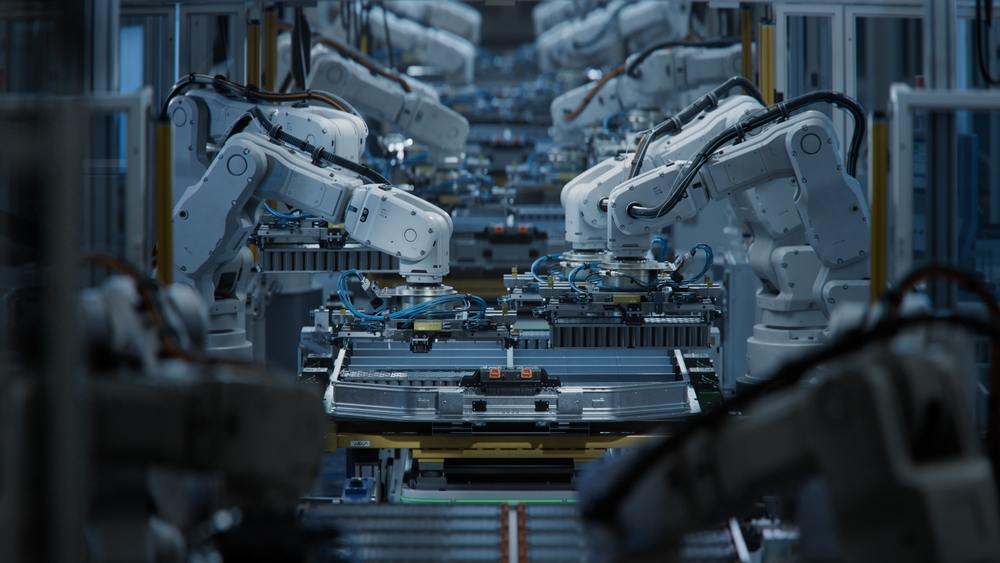

With the rise of technology and AI, manufacturing solutions are starting to resemble the stuff of science fiction stories. Automation is making factories faster, safer, and more efficient than ever before.

But what exactly is manufacturing automation? It means using machines, computers, and smart technology to make products with little to no help from humans. With automation, businesses can produce goods more quickly, with better quality, and at a lower cost. Companies that do not use automation may struggle to keep up in today’s fast-paced world.

If you own or work in a business that makes products, now is the time to learn about automation. Whether you want to improve the way things are done or switch to a fully automated system, understanding this technology is key to staying competitive. We can help you with that! Let’s dive into what manufacturing automation is and how our team can bring it to your business.

What is Manufacturing Automation?

Manufacturing automation is the use of technology to complete tasks that humans used to do. These tasks are often repetitive, like putting parts together, moving materials, or inspecting products. Automation can be as simple as a conveyor belt moving items down a production line or as complex as a robotic arm assembling cars. The goal isn’t to replace humans but to free up their time to focus on less rote tasks.

Industries That Use Automation

Automation is used in many different industries, including:

- Car manufacturing – Robots help put together vehicles quickly and with great accuracy.

- Electronics – Machines create and test products like smartphones and computers.

- Pharmaceuticals – Automated systems mix and package medicines to make sure they are safe.

- Food processing – Factories use machines to sort, package, and check food quality.

- Aerospace – Robots help build airplane parts with high precision.

Types of Automation

Not all manufacturing automation is the same. Different industries use different types of automation based on their needs.

Fixed Automation

Fixed automation, or hard automation, is used when a company needs to make the same product over and over again. Machines are built to do one specific job, like assembling cars. This type of automation is very fast and efficient but is not easy to change if the company wants to make a new product.

Programmable Automation

This type of automation allows machines to be reprogrammed to make different products. Factories that produce electronics or household goods use this type of automation. They often need to switch between making different items.

Flexible Automation

Flexible automation is the most advanced. It allows robots and machines to change tasks quickly. This is useful in industries where products change often, such as aerospace and custom machinery production.

We can help you engineer and design any of these types of automation systems, it just depends on what your business produces. Whether you make aerospace machinery or oil rig parts, our Houston-based team is on it.

The Role of AI, Robotics, and IIoT in Automation

Automation is not just about robots. It also involves artificial intelligence (AI) and the Industrial Internet of Things (IIoT).

- AI helps machines make smart decisions by analyzing large amounts of data. This type of AI isn’t the same as ChatGPT. All of the data we feed it is related to your industry and what your machinery needs to do.

- Robots perform precise, repetitive tasks without making mistakes.

- IIoT connects machines to the internet so they can communicate and share information in real time.

Together, these technologies create smart factories where machines work efficiently with little human supervision.

Benefits of Manufacturing Automation

There are several benefits to implementing manufacturing automation into your workflow. The following four are the ones that stand out the most to us:

- Faster Production Without Sacrificing Quality: Automated systems can make products much faster than humans while maintaining high quality. Machines follow instructions perfectly every time, which means fewer mistakes.

- Reducing Human Error and Improving Safety: Humans make mistakes, especially when we are tired or distracted. Automation reduces these errors by having machines do the work instead. It also makes workplaces safer by keeping workers away from dangerous tasks. That way your employees aren’t handling heavy materials or working with toxic chemicals.

- Lower Costs and Higher Profits: At first, automation can be expensive to set up. However, in the long run, it saves money by reducing labor costs, minimizing waste, and increasing production speed. Businesses that use automation can make more products at a lower cost, leading to higher profits.

Challenges of Manufacturing Automation

While automation has many benefits, businesses must also consider potential challenges.

- Upfront Costs: Setting up an automated system can be expensive. However, the long-term savings and efficiency improvements usually make it worth the investment.

- Job Changes in the Workforce: Automation does not always mean job losses, but it does change the types of jobs available. While some positions may no longer be needed, new jobs in programming, maintenance, and system management will be created.

- Cybersecurity Risks: We would be remiss to avoid talking about the cybersecurity risks. Anytime we connect machines to the internet, companies must protect their systems from hackers. Strong cybersecurity measures help keep factory operations safe from cyber threats.

Unleash Kraken’s Automation Services

Automation is transforming manufacturing, making it faster, safer, and more efficient. Companies that invest in automation now will have a competitive advantage in the future.

If your manufacturing business wants to start using automation, here are some steps to take:

- Evaluate your current processes – Identify tasks that could be automated.

- Research automation solutions – Look into different types of automation and technologies.

- Consult with experts – Talk with experts like Kraken Engineering to implement automation processes into your organization.

- Train your workforce – Teach employees how to work with new automated systems.

- Maintain and optimize – Regularly review and improve automation systems to ensure efficiency and adapt to evolving needs.

By taking these steps, businesses can improve efficiency, reduce costs, and stay ahead in an evolving manufacturing world.

Contact us for a free consultation today – we’d love to help you!